| Engineering

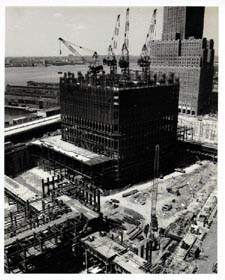

The achievement of the Twin Towers depended upon innovative engineering. As both client and construction manager, the Port Authority engaged in a program of research and analysis that sought efficiency for the sake of economy and also for the intelligence of the engineering solutions. There were several principal areas of innovation: The Twin Towers were the first supertall buildings to use "tube" construction, a structural system in which the outside walls act as a thin-shell or tube, cantilevering from the foundations to resist hurricane winds and earthquakes and to stabilize the core against lateral buckling. The system eliminated the need for a conventional rigid-frame, reduced the story height to 12 feet, and allowed column-free space of a 60-foot clear span, with less steel and a lower story height than is found in most 50-story buildings. Extensive use of wind tunnel testing to analyze the aeroelastic behavior of the structural system and pressures on the cladding was used for the first time in America. This study was coupled with an exhaustive statistical analysis of building motion, as well as a physiological study of human sensitivity to transverse oscillation, or sway. The prefabrication of structural components was developed to a point unprecedented in high-rise buildings, and the detailed design for most of the steel work was presented to manufacturers for the first time in digital format on IBM punch cards. For the excavation of the foundations of the 16-acre site, known as "the bathtub," the method of slurry-wall construction was used for the first time in the United States. Other firsts included: the use of damping devices incorporated into the structural system and the development of a new partition called "Shaftwall" that eliminated masonry in the building core. |